Modern measuring microphones in the classic design as condenser microphones change their parameters very little, even over years. If stored carefully, they can generally be used for decades. However, measurement microphones are exposed to other stresses in everyday life.

What happens if a measurement microphone falls on the floor?

How often does it happen that a measurement microphone simply falls off the table?

From the outside you might encaounter a small dent on the protective grid. But......

A visual inspection of the membrane provides initial information. This must be flat and must not have any dents or holes. This would be a total loss.

The following picture shows three 1/2" capsules without a protective grid.

The left capsule is normally functional with a smooth membrane.

The membrane in the middle one has been removed and the back-electrode can be seen. The holes in the back-electrode serve to specifically dampen the membrane movement.

The right capsule is damaged by falling. The membrane no longer fits smoothly. In this example the defect is clearly visible. In practice, however, the damage can be more subtle and difficult to see visible visually.

Even if no damage is immediately visible at first, the membrane may no longer have the mechanical tension that was precisely set by the manufacturer.

How can you check microphones yourself?

- Visual inspection of the membrane . Unscrew the protective grid. Hold the microphone up to the light and examine the membrane. This must be flat and without dents or holes. Under no circumstances touch the membrane.

If you find any damage to the membrane, this is a total loss and the capsule must be replaced. - Check sensitivity with a sound level calibrator . The sensitivity is given in mV/Pa. Compare this value with the information from the calibration protocol. The most common 1/2" measuring microphones have a sensitivity of approx. 50mV/Pa. Many sound level meters directly display the measured sensitivity. The measurement is usually carried out at 1kHz and 94dB. However, there are also calibrators with extended frequencies, for example 125Hz, 250Hz or 500Hz.

- Comparison measurement with a functional capsule. Place a loudspeaker about 1m away from the microphone. Play pink noise through the speaker. Measure the level in third octave bands with both microphones one after the other and compare. The deviations should be within the range of DIN/IEC61672-1. However, this measurement basically also records the influence of the room and can therefore only provide indications.

Ultimately, if capsules are unclear, the frequency response must be measured in the laboratory. This is the only way to check that the manufacturer has correctly adhered to the specification.

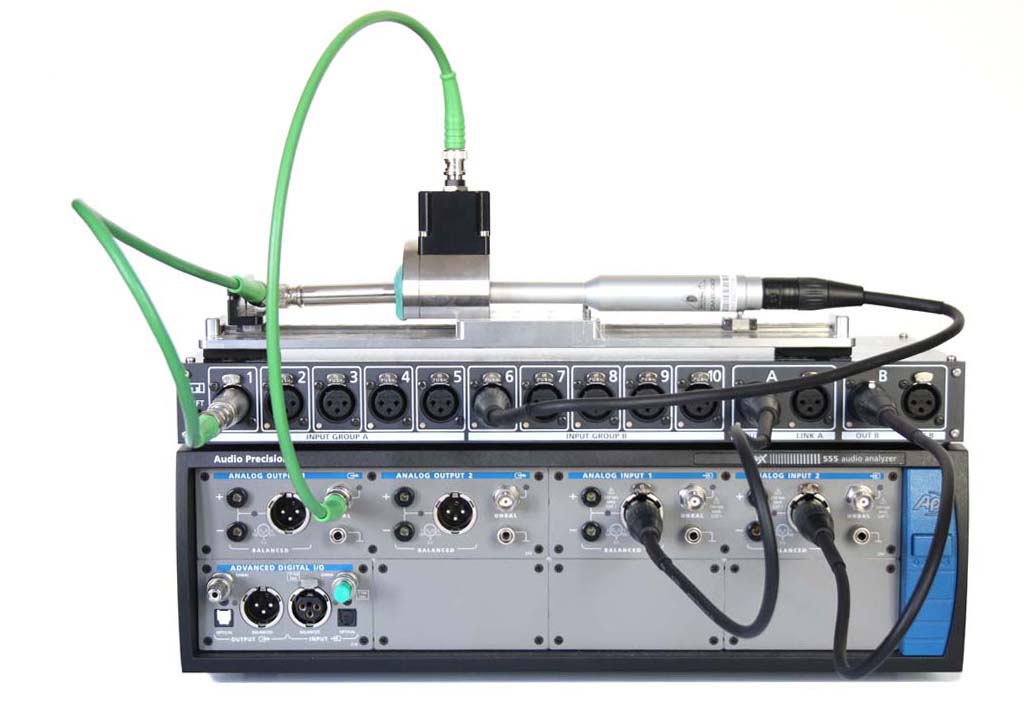

We carry out such measurements economically using a precision pressure chamber. We use an automated measuring station that records all relevant parameters. You will receive a full report.